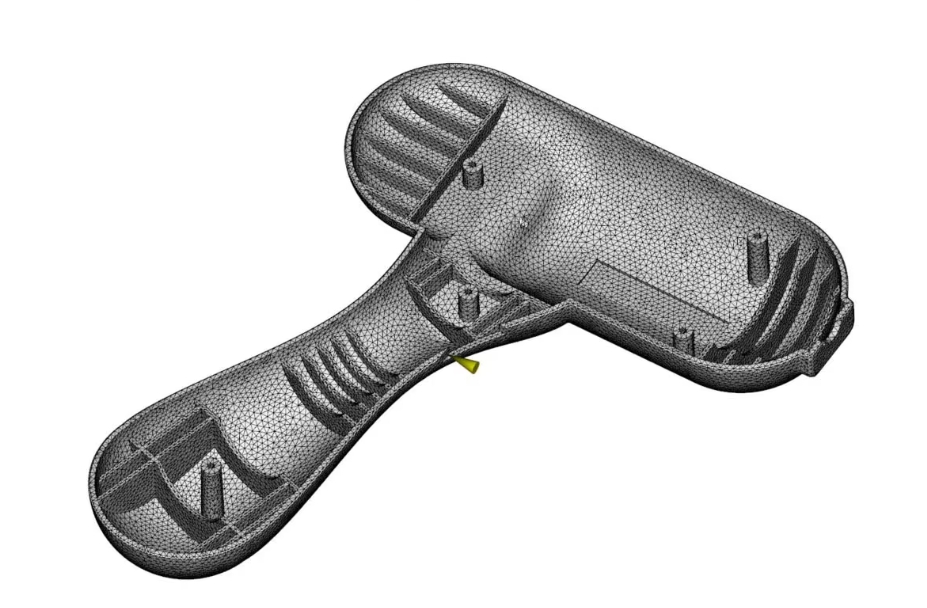

Plastic Injection Mold Flow Analysis

Mold Flow Analysis application on Plastic injection Mold design optimization

Mold flow analysis (MFA) is a crucial tool in the field of mold design optimization. It involves simulating the flow of molten plastic material inside a mold cavity during the injection molding process. By utilizing specialized software, engineers can predict and visualize how the molten plastic will behave under various conditions, allowing them to optimize the design of the mold for better performance and efficiency. Here's how MFA is applied to mold design optimization:

-

Identifying Potential Issues: Mold flow analysis helps engineers identify potential problems in the mold design before manufacturing begins. This includes issues such as air traps, weld lines, shrinkage, warpage, and uneven filling of the mold cavity. By spotting these issues early on, engineers can make necessary adjustments to the mold design to prevent defects in the final product.

-

Optimizing Gate Locations: The location and size of the gate (the point where molten plastic enters the mold cavity) have a significant impact on the flow of plastic within the mold. MFA allows engineers to experiment with different gate locations and sizes virtually to optimize the filling pattern, minimize pressure drop, and reduce cycle time.

-

Balancing Runner Systems: In multi-cavity molds, it's essential to ensure that each cavity fills uniformly to produce consistent parts. MFA helps in balancing the runner system by adjusting the size and layout of runners and gates. This ensures that each cavity receives an equal amount of molten plastic, reducing variations in part quality.

-

Cooling System Design: Efficient cooling is critical for maintaining cycle times and controlling part quality. MFA can analyze the cooling process within the mold, predicting temperature distribution, cooling rates, and potential hot spots. Engineers can then optimize the design of cooling channels to achieve uniform cooling and minimize cycle times.

-

Material Selection: Mold flow analysis can assist in selecting the appropriate material for the injection molding process. By simulating how different materials flow and behave during molding, engineers can choose materials that meet performance requirements while optimizing processing parameters such as melt temperature and injection pressure.

-

Predicting Warpage and Shrinkage: MFA provides insights into how the molded part will deform and shrink as it cools down. This helps engineers anticipate potential warpage issues and take preventive measures such as adjusting part geometry, optimizing gate locations, or modifying the cooling system to minimize distortions in the final product.

-

Iterative Design Improvement: Mold flow analysis is an iterative process where engineers can make design modifications based on simulation results to achieve the desired outcomes. By repeating simulations with different parameters, engineers can gradually refine the mold design until it meets all performance and quality criteria.

Overall, mold flow analysis plays a vital role in mold design optimization by providing valuable insights into the injection molding process, allowing engineers to make informed decisions and create molds that produce high-quality parts efficiently.

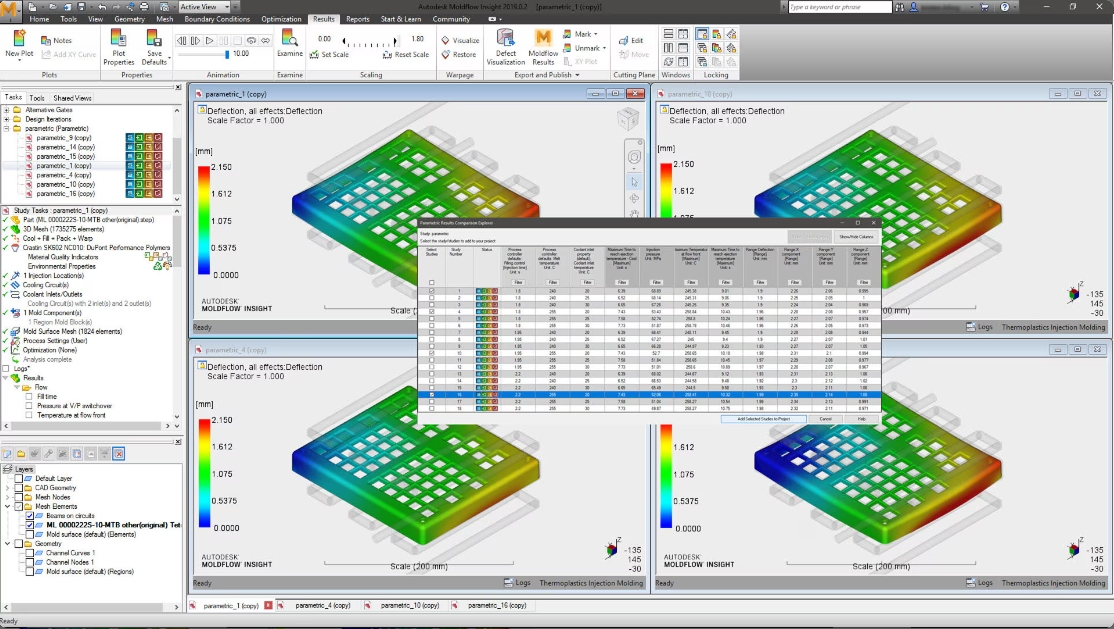

Ming-Li use Autodesk Moldflow System

Autodesk® Moldflow® simulation software provides plastic injection molding and compression molding insights to improve manufactured part quality. Advanced tools and a simplified user interface help you address manufacturing challenges such as part warpage, cooling channel efficiency, material selection, and cycle time reduction.

Choosing Autodesk Moldflow Analysis software offers several advantages for engineers and designers involved in mold design optimization and injection molding processes:

-

Improve part quality: Predict as-manufactured part quality and address part defects earlier.

-

Minimize mold rework: Optimize mold designs including cavity, feed, and cooling layouts.

-

Decrease cycle time: Utilize process optimization to find the ideal processing window.

-

Comprehensive Simulation Capabilities: Autodesk Moldflow provides a comprehensive suite of simulation tools that cover various aspects of the injection molding process, including flow analysis, cooling analysis, warpage prediction, fiber orientation, and much more. This breadth of capabilities allows engineers to thoroughly analyze and optimize their mold designs.

-

Accurate Predictions: Autodesk Moldflow uses advanced algorithms and solvers to accurately predict how molten plastic will behave during injection molding. This includes predicting flow patterns, pressure distribution, temperature gradients, and part shrinkage with high precision, helping engineers make informed decisions to optimize their designs.

-

User-Friendly Interface: The software features a user-friendly interface that allows engineers to set up and run simulations efficiently. It offers intuitive workflows, interactive visualization tools, and customizable simulation settings, making it accessible to users with varying levels of experience in simulation and mold design.

-

Integration with CAD Software: Autodesk Moldflow seamlessly integrates with popular CAD software like Autodesk Inventor and Autodesk Fusion 360, allowing engineers to directly import their CAD models into the simulation environment. This integration streamlines the workflow and facilitates seamless data exchange between the design and analysis stages.

-

Design Optimization Tools: The software includes powerful design optimization tools that enable engineers to iterate on their designs quickly and efficiently. By performing parametric studies, sensitivity analyses, and optimization algorithms, engineers can identify the most critical design parameters and optimize their mold designs to achieve desired performance metrics.

-

Material Database and Material Selection Tools: Autodesk Moldflow provides access to an extensive material database containing a wide range of thermoplastic and thermoset materials. Engineers can easily select the appropriate material for their application based on material properties, processing parameters, and compatibility with the injection molding process.

-

Technical Support and Resources: Autodesk offers comprehensive technical support and resources to assist users in getting the most out of the software. This includes documentation, tutorials, online forums, and direct support from Autodesk's technical experts, ensuring that users have the assistance they need to overcome any challenges they encounter.

Overall, Autodesk Moldflow Analysis software offers a powerful and versatile solution for mold design optimization, providing engineers with the tools and capabilities they need to simulate, analyze, and optimize their injection molding processes effectively.