PEEK molding / PEEK injection

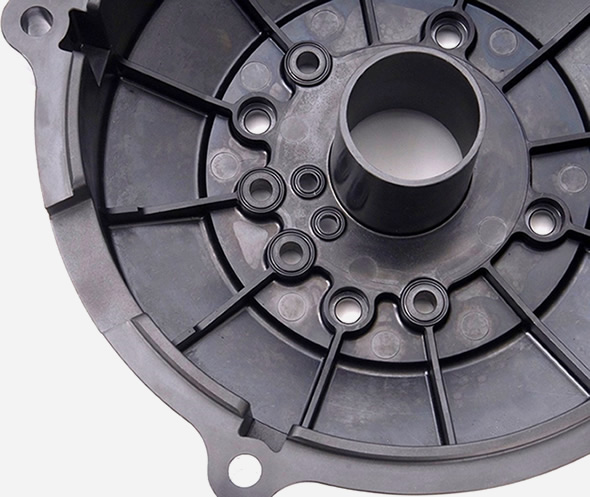

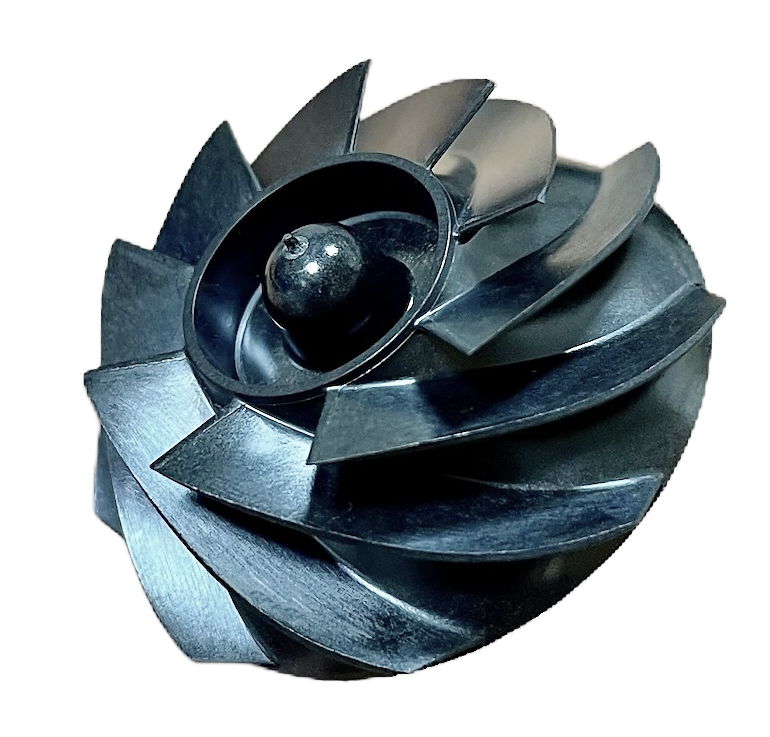

Application: for Automotive, Aerospace, Defense, Pump and Oil & Gas industry

We have invested significant resources to develop industry leading expertise in PEEK molding / PEEK injection part and other advanced material applications.

With our world class in-house engineering, design, tooling and processing capabilities, MING-LI can work with you from the PEEK material mold design concept stage to high volume PEEK injecetion parts mass production. By incorporating PEEK tooling and PEEK injection parts manufacturing improvements throughout the development cycle, MING-LI can help you optimize your PEEK material component for production, bringing real value to your organization.

Ming-Li offers PEEK injection molding of all Victrex PEEK, RTP PEEK, Luvocom PEEK and others PEEK material grades. Our in-house peek injecction molding operation uses all electric machines with appropriately sized barrels minimizing time at temperature during PEEK molding to maximize the properties and consistency of every part we molded. Our range of machine sizes between 15 to 320 tons means we can mold PEEK molding parts ranging in size from 0.1 g. to 600 g.

We design our process to meet your needs. Our PEEK injection-compression molding machines combined with our experience processing PEEK injection enables us to do what others cannot: precision tolerances, zero draft, fiber orientation, insert molding and heavy cross sections. All machines are RJG equipped allowing us to monitor in-cavity conditions and develop the most reliable PEEK molding process for a given part. We apply scientific molding principles when molding PEEK injection parts.

We are recognized as a leading molder of high temperature PEEK injection and PEK based polymers.

Our PEEK Molding Services

Injection Molding / Medical Molding / Overmolding / Insert Molding / Micro Molding / Ultrasonic Bonding

Considerations for PEEK Injection Molding

Fortunately, Ming--Li has the skills, experience, and advanced machinery needed to effectively work with PEEK plastic in all our plastic injection molding processes. We provide unparalleled expertise in injection moulding PEEK resin for medical devices and other applications.

- All runs start with a clean barrel and end with a complete teardown

- Dedicated membrane dryers and moisture recorded before every run is started

- All tools are oil heated for uniformity

- PEEK Near Net Shapes offer a balance between the cost effective conversion of injection molding and the precision of CNC machining.

Near Net Shapes – What are their benefits?

Near net shapes are great for geometries that result in a poor machining yield from a stock shape or those requiring complex tools that are not cost justified by the volume of parts.

Injection Molding with PEEK Resin application

Ming-Li works with a wide variety of materials in our injection molding processes. The high strength-to-weight ratio and heat tolerance of PEEK plastic makes it a popular choice for a wide range of applications including aerospace, biomedical, pharmaceutical, fiber optics, automotive, industrial, and more. In addition to standard injection molding, PEEK resin is also used in overmolding applications to fabricate reinforced components for aerospace and automotive.

Application of PEEK Components:

- Tubing

- Profiles

- Bearings

- Seals

- Valves

- Electrical cable insulatioon

- Medical implants

- And more

PEEK material Properties

PEEK plastic exhibits superb mechanical properties and is highly resistant to chemicals and thermal degradation, making it a highly desirable material for plastic injection molded products. PEEK resin holds up well against high temperatures and long-term liquid submersion and is very durable in harsh environments. PEEK plastic makes an excellent reinforcement material, providing great tensile strength with low weight.

Features and benefits of PEEK material properties include:

- High chemical resistance, even at elevated temperatures

- High hardness, stiffness & strength

- Excellent fatigue & stress-crack resistance

- Excellent resistance to high pressure water & steam without significant degradation

- Can be sterilized via autoclave

- Easy to machine & fabricate

- UL 94 V-0 flammability rating

- Very low smoke/toxic gas emission when exposed to flame

- Suitable for continuous use in application temperatures up to 338°F/170°C

- Unfilled PEEK is FDA-approved for food contact

Key elements for successful PEEK injection molding include:

-

Material Selection: Choose the appropriate PEEK material grade based on the specific application requirements, considering factors such as mechanical properties, temperature resistance, chemical resistance, wear resistance, and regulatory compliance.

-

Mold Design: Design the mold with precision to accommodate the desired part geometry, gating, venting, and cooling requirements for PEEK injection molding. Consider features such as draft angles, parting lines, and vent channels to facilitate mold release and minimize defects.

-

Tool Fabrication: Fabricate the mold tooling using high-quality materials and precision machining techniques to achieve tight tolerances, smooth surface finishes, and durability. Verify the accuracy of the mold components through thorough inspection and validation.

-

Injection Molding Machine: Utilize a well-maintained injection molding machine with appropriate specifications for processing PEEK material, including barrel temperature control, injection pressure capability, injection speed control, and shot size capacity.

-

Injection Process Optimization: Optimize process parameters such as barrel temperature, injection pressure, injection speed, cooling time, and hold pressure to achieve consistent part quality, minimize cycle times, and prevent defects such as warpage, sink marks, or surface blemishes.

-

Injection Unit: Ensure that the injection unit is properly calibrated and equipped with precision metering and mixing systems to accurately dispense the PEEK material into the mold cavity. Pay attention to screw design, back pressure control, and screw/barrel alignment to prevent material degradation and ensure uniform melt quality.

-

Mold Temperature Control: Maintain precise control over mold temperature using water or oil circulation systems to achieve uniform cooling and solidification of the PEEK material, preventing defects such as warpage, shrinkage, or surface irregularities.

-

Venting and Degassing: Ensure proper venting and degassing of the mold cavity to eliminate trapped air and gas bubbles during the injection process, preventing defects such as voids, bubbles, or surface imperfections in the molded parts.

-

Part Ejection and Handling: Implement reliable part ejection mechanisms (e.g., ejector pins, air ejection) and handling systems to safely remove the molded parts from the mold cavity without damage or deformation.

-

Quality Control and Inspection: Establish comprehensive quality control measures and inspection procedures to monitor part dimensions, surface finish, and physical properties. Conduct regular inspections and testing to verify part quality and consistency.

-

Training and Expertise: Ensure that operators and technicians receive proper training and have expertise in PEEK injection molding techniques, equipment operation, mold maintenance, and troubleshooting to address any challenges that may arise during production.

By addressing these key elements and optimizing the PEEK injection molding process, manufacturers can produce high-quality, precision-molded parts with consistent performance and reliability for a wide range of applications.

PEEK Material using in Ming-Li

- Victrex PEEK HT G22

- Victrex PEEK 450G

- Victrex PEEK 150CA30

- Victrex PEEK 450CA30

- Victrex PEEK WG102

- Victrex PEEK 450FC30

- Victrex PEEK 150FC30

- Victrex PEEK 450FE20

- Victrex PEEK 450GL30

- Victrex PEEK ST 45GL30

Let us apply our process know-how to arrive at the most cost effective process to manufacture your PEEK molding parts. We will work with your existing tooling or develop new tooling.

Click here to contact us or request information regarding our products.