Gas Assist Injection Molding Technology

Internal gas pressure technology

The gas-assisted injection molding process application in Ming-Li

Ming-Li internal gas pressure injection molding is a process in which nitrogen is injected into the mold cavity partly or completely filled with melt. The pressurized gas forms a bubble at the center of the melt, which counteracts shrinkage contraction on the outside and thus eliminates sink marks. By reducing the amount of plastic and enlarging the central cavity, it is possible to produce specific lightweight components with short cycle times and simultaneously good surface quality. This process opens up good opportunities for molded part designers to produce complex parts with smooth surfaces in one piece.

Advantages of Airmould application:

- Quality improvement

- Weight reduction

- Plastic material savings

- Reduction of component unit costs

- Prevention of sink marks

- Reduction / prevention of warpage

- Design freedom

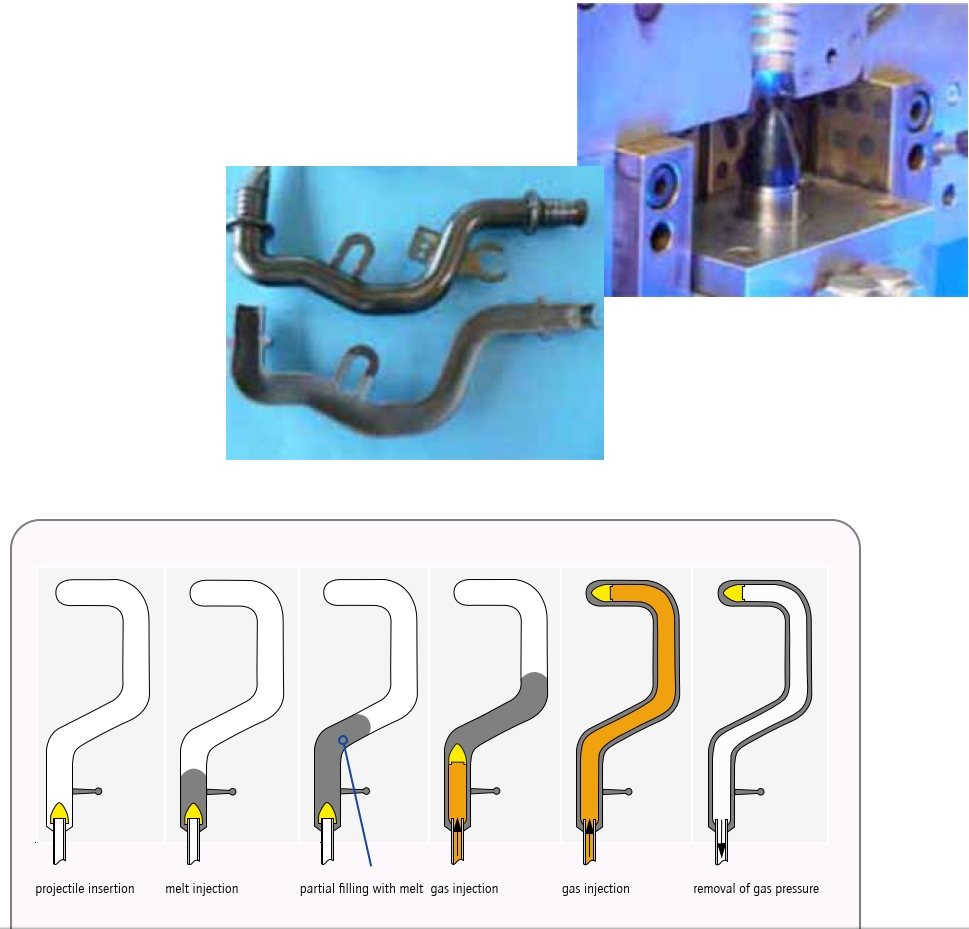

Projectile injection process

With this fluid injection technology, a displacement body (projec-

tile) is driven under gas pressure through the previously injected

melt. The projectile displaces plastic melt and thus forms a cavity

with a uniform diameter. This process is particularly recom-

mended for pipes and media conduits. Handles and other parts

with sizeable hollow spaces of uniform diameter can also be

produced with projectile injection technology.

The process variants in detail

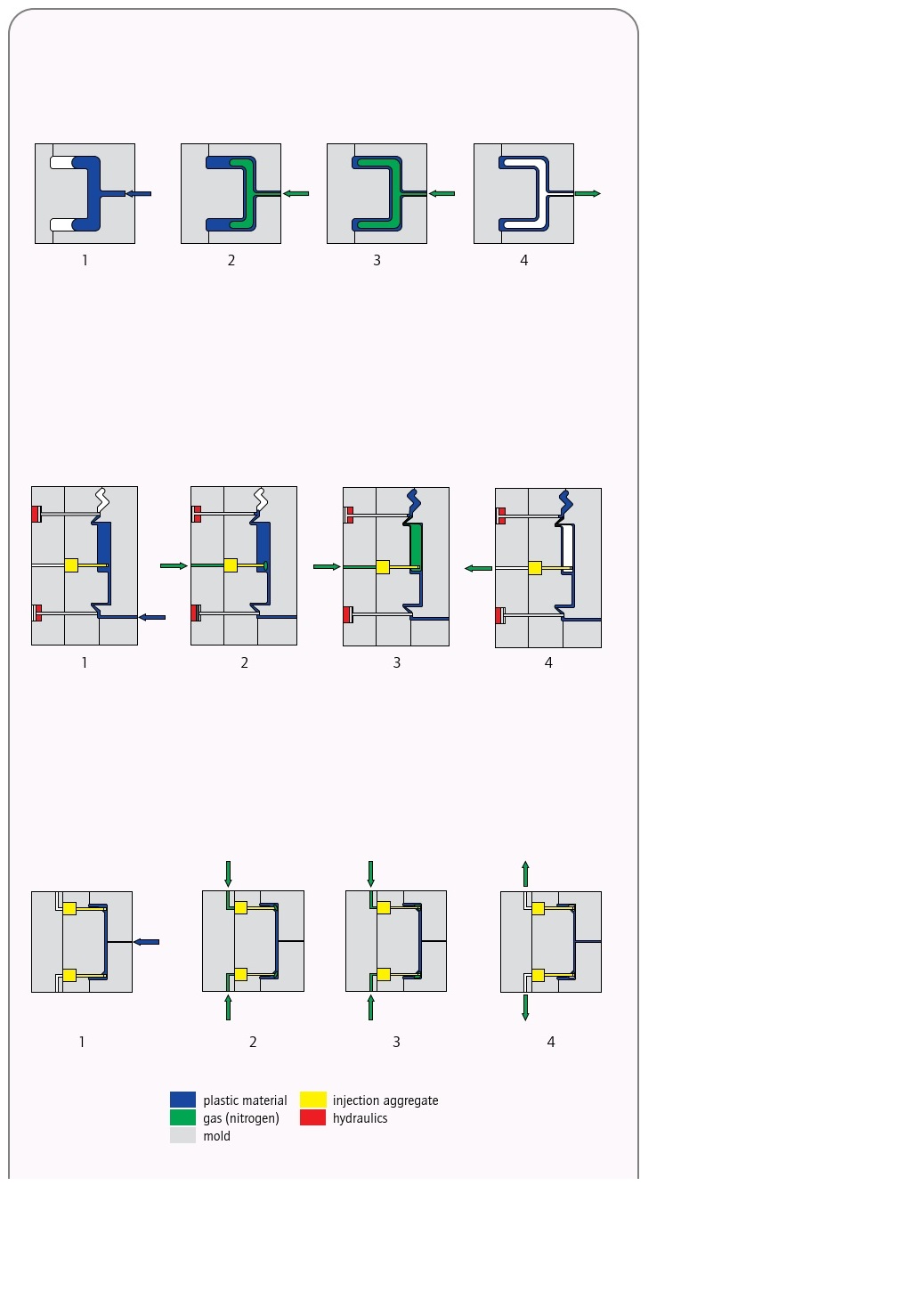

» Partial filling process

Partial filling is the standard process.

The cavity is partially filled with melt [1].

Next, gas is injected. It forms a gas bub-

ble inside the hotter core area with lower

viscosity and displaces this part of the

melt until the cavity is completely filled

[2]. The gas pressure is maintained as

holding pressure for shrinkage compensa-

tion [3] and finally removed prior to mold

opening [4]. Gas injection through the

Airmould nozzle of the machine serves to

seal the sprue.

» Spill-over cavity process

As process step No. 1, the cavity is com-

pletely filled with melt [1]. If necessary,

holding pressure is applied to the melt.

Then the spill-over cavity (overflow) is

opened and nitrogen injected [2]. The gas

displaces melt from the core area of the

plastic material into the overflow. Subse-

quently, the gas pressure is maintained

as holding pressure throughout the entire

cooling period [3] and thus counteracts

shrinkage. The gas pressure is removed

prior to opening the mold [4].

» Shrinkage compensation process

First, the cavity is completely filled with

melt [1]. Then nitrogen is injected [2]

and supplies the holding pressure to

counteract shrinkage [3]. The gas forms

channels inside the molded part, in which

gas pressure is maintained throughout

the cooling period and thus counteracts

shrinkage. Depending on the molded

part, the gas is injected either through ag-

gregates inside the mold or the Airmould

nozzle of the machine. The gas pressure is

removed prior to mold opening [4].

Gas assist injection molding is a variation of conventional injection molding that utilizes an inert gas, typically nitrogen, to assist in the molding process. In gas assist injection molding, the gas is injected into the mold cavity after the initial injection of molten plastic resin. This gas forms hollow sections or channels within the part, reducing material usage, cycle times, and part weight while improving surface finish and dimensional stability.

Here's how the gas assist injection molding process works:

-

Initial Injection: The process begins with the injection of molten plastic resin into the mold cavity through the primary injection unit. This initial shot fills the mold partially, leaving space for the gas to be introduced later.

-

Gas Injection: After the initial injection, a gas injection unit introduces a controlled volume of inert gas, typically nitrogen, into the cavity. The gas flows through strategically placed channels or nozzles within the mold, displacing the molten plastic and forming hollow sections or channels within the part.

-

Pressure Maintenance: Once the gas has been injected, the gas pressure is maintained within the cavity for a specified period, typically until the part cools and solidifies sufficiently to maintain its shape. This pressure helps to support the walls of the part, preventing collapse or deformation as the plastic cools.

-

Cooling and Solidification: As the part cools, the gas pressure is released, and the plastic solidifies around the gas channels. The cooling process may be accelerated by the use of cooling channels within the mold. Once the part has fully solidified, it is ejected from the mold cavity.

Benefits of gas assist injection molding technology include:

-

Reduced Material Usage: Gas assist injection molding allows for the creation of hollow sections or channels within the part, reducing the overall material usage while maintaining structural integrity and strength.

-

Cycle Time Reduction: By forming hollow sections within the part, gas assist injection molding can reduce cooling times and cycle times compared to solid parts, leading to increased production efficiency and throughput.

-

Part Weight Reduction: The incorporation of hollow sections or channels in the part design enables significant weight reduction, making gas assist injection molding suitable for applications where weight savings are desirable, such as automotive and aerospace components.

-

Improved Surface Finish: Gas assist injection molding can improve the surface finish of parts by reducing sink marks, warpage, and surface defects commonly associated with solid injection-molded parts.

-

Enhanced Design Flexibility: Gas assist injection molding offers greater design flexibility, allowing for the creation of complex geometries, undercuts, and integrated features that may be challenging or impossible to achieve with conventional molding techniques.

-

Reduced Tooling Costs: Gas assist injection molding may reduce tooling costs compared to other molding processes by enabling the use of smaller, less complex molds due to the reduced material requirements and lower clamping forces.

Overall, gas assist injection molding technology offers numerous advantages for manufacturers seeking to produce lightweight, high-quality plastic parts with complex geometries and improved surface finish while reducing material usage and cycle times.